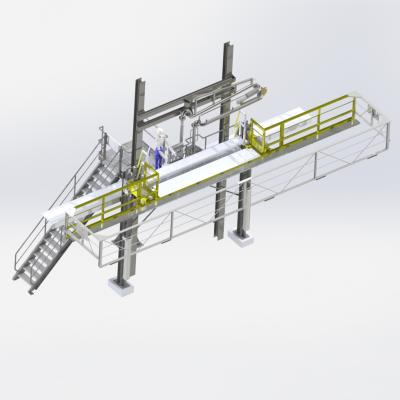

VARIABLE-REACH TOP LOADING ARMS

For loading tankers with multiple tanks

The loading arms for operations from several manholes

Large deployment zone at the top of the tanker

Strengths and specificities

- For carrying out fluid loading operations with access to several manholes without having to move the lorry

- A technical loading arm that is compatible with all types of tanker (including ISO containers)

- Available in an automated version on every axis on request

Conditions of use

The conditions of use depend on several factors (installation environment of the arms, service conditions and fluid characteristics). Let's find the right loading arm for you: send us your SDS (safety data sheets).

STANDARD TECHNICAL CHARACTERISTICS OF THE VAARIABLE-REACH LOADING ARM

- Steel or stainless steel construction as standard

- Balancing using gas-spring compensators as standard

- “Arm on the right”/“arm on the left” orientation according to your installation

- Version that is fastened to the ground or a support beam, or a hanging version

- Top or bottom side feed

OPTIONAL EQUIPMENT AVAILABLE

- Fastened with a support bracket

- Pneumatic assistance (helps with handling the loading arm) and remote control with reinforced sleeve

- Level sensor (anti-overflow probe)

- Vapour recovery duct

- Positioning cone or hood with flaps

- Vacuum breaker

- Drip box

- Single butterfly valve or double offset butterfly valve

- Ball valve

- Remotely controlled valve opening/closing control

- Drain valve

- Locking in loading position

- Locking in storage position

- Position detector

- Dead man command

- Electric tracing or double jacket heating of the arm (heat-transfer fluids)

- Thermal insulation

- Specific paint finish

- Specific coatings on request

- Atex archiving

FDA compatibility (food applications) available on request - Specify ATEX zoning if applicable - CE marking for pneumatic, electrical equipment, or equipment used in ATEX zone - Specify if the loading arm is subject to the EU pressure equipment directive

Are gangways or folding stairs already installed on site? Beware of the risk of incompatibility between the existing gangway and the loading arm to be installed. Pacquet develops and designs all-inclusive loading systems with arms and tanker top access gangways. More information from our teams.